From economic narrowband systems to high-throughput commercial timber processing lines, Wood-Mizer’s Sawmilling Solutions team are available to design the ideal system to meet your requirements. Below are just some examples of the complex and customizable lines that can be designed completely to meet your needs. Wood-Mizer’s global engineering team and systems specialists look forward to hearing your challenges and planning new solutions that will achieve your goals.

World Class Sawmill Systems / Development

Customized System Design

With your input, our experienced design engineers can tailor a system that is perfect for your operation's needs, goals, and budget. Our dedicated team is focused on helping you build a long-term solution for your business and receive the maximum value for your investment.

Detailed Project Management

We will work closely with you to optimize your production, guarantee an efficient operation and make sure your project keeps moving forward with transparency and detailed communication. This includes preliminary designs, cost estimates, feasibility analysis, execution methods and installation, an agreed-upon schedule, and more.

World-Class Manufacturing

With 100,000+ sawmill operations in more than 100 countries, Wood-Mizer is the undisputed global leader in thin-kerf sawmilling equipment. We use modern design and manufacturing techniques including 3D CAD, laser profiling, CNC bending and CNC machining. Our onsite machinery and technology allows us to build heavy-duty, durable, and high-value systems that are running efficiently in customer operations all around the world.

In-Depth Training & Installation

Our team will provide in-depth training on the equipment for the mill personnel, track the installation progress and make all necessary adjustments to guarantee the installation is completed successfully. Our mission is to be your long-term partner in the sawmilling industry, and we do that by standing behind our products and providing premium after sales service experience.

World Class Sawmill Systems / Videos

World Class Sawmill Systems / Options

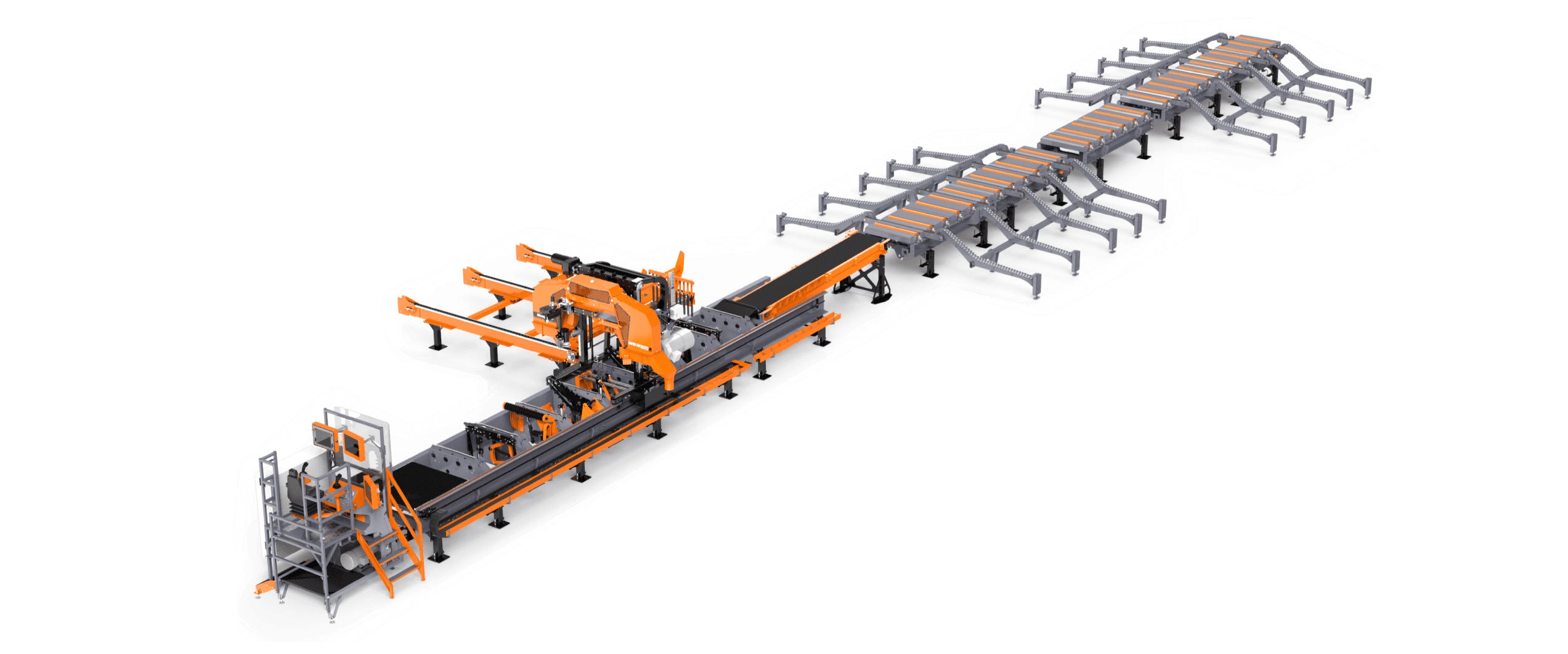

Wood-Mizer’s LT70 Remote integrated sawmill systems give you everything you need to process logs into finished boards more profitably with minimal expense and labour. The LT70 Remote sawmilling systems deliver maximum production using Wood-Mizer’s orange line of sawmills. The productivity, higher log yields, affordability and low operating costs make these systems very viable solutions.

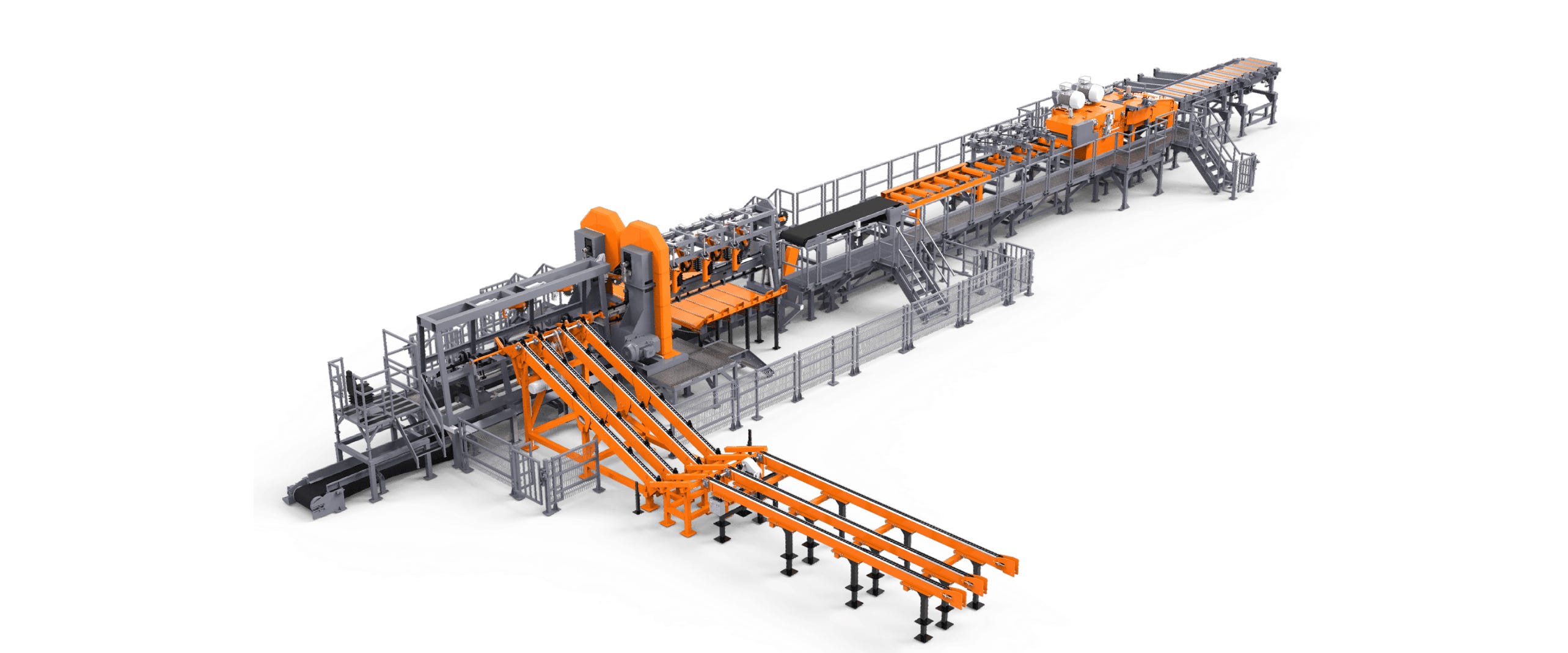

Industrial sawmilling systems combine the profitability enhancements of thin-kerf blades with commercial productivity to create an ideal solution for any sawmill. Configurable for whatever production requirements are needed, industrial sawmilling systems deliver higher log yield at lower investment and operating costs than alternatives while increasing profitability and the ability to produce diverse products. Powerful hydraulic log handling enable easy manipulation of large logs and several options are available to meet your needs.

Wood-Mizer’s WB2000 features heavy-duty construction, low maintenance requirements, and efficient operation. The WB2000 uses wideband 3" blades or 4" stellite-tipped blades. When using 3" blades the sawmill is especially cost-efficient in terms of blade maintenance costs. To ensure the best visibility of the cutting and log handling processes we offer an optional live-feed video system with two cameras as standard, expandable up to four cameras. The PRO version of the sawmill uses an automatic PLC setworks system. The 12-inch touch-screen displays various parameters such as the dimensions of the material, current head height, feed position and main engine power. To adjust these parameters, the operator simply has to use the touch screen to enter new settings. The EC version uses a 5.7-inch touch-screen with the latest version of the SW PLC3 Setworks system. The modern, heavy-duty bed has a log capacity of up to 6 tons. The massive twin C-channel steel beams that make up the frame are 15 3/4" tall by 4 5/16" wide. All hydraulic log handling functions - such as the log clamps, chain turners, power rollers, side supports and hold-down clamps - are modular, and can be moved to different bunks as needed.

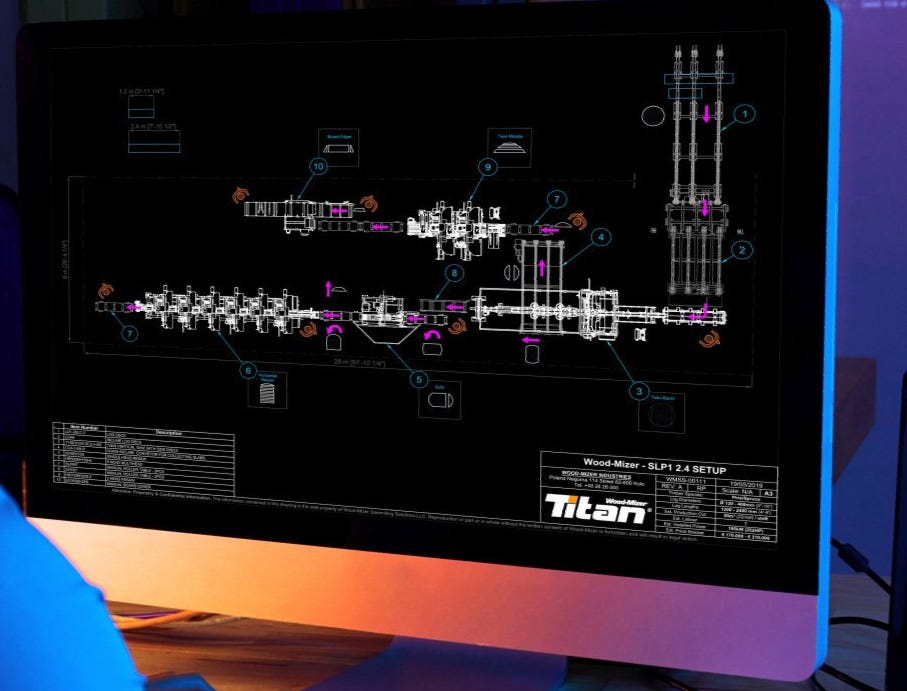

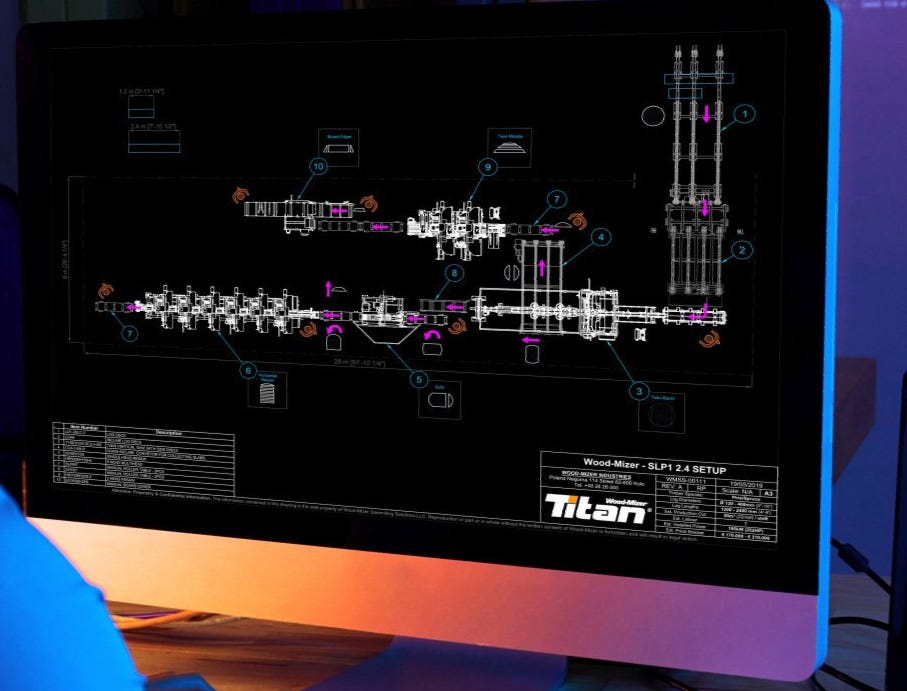

A log processing line that maximises log yield and minimises investment and operational costs. The SLP (Smart Log Processing) line uses thin-kerf blades on each sawmill unit in the line to deliver better log yield than other processing methods. Highly popular among pallet manufacturers, the SLP specializes in making the most profit possible from low value logs up to 400mm in diameter and increasing your competitive edge. Because the line is modular, machines in the line can be arranged to suit cutting needs as the market changes. Typical components include a Twin Vertical Saw, a Single Vertical Saw, a Multihead Resaw and a Multirip or Edger.

The TV2000 is an efficient and robust twin vertical saw for small to medium diameter logs up to 4m in length. It is designed to break the log into a two-sided cant. The mechanised log loader allows for a single operator to rotate each log to the optimal position and then place it onto the moving sharp-chain. While moving through the blades, the log is held stable by multiple pressure feed rollers from the top, giving it unrivaled stability in the cut. The operator may select the desired cutting size and the machine will automatically adjust to that size in a fraction of a second, making it possible to saw unsorted logs, although Investing in log sorting capability increases log throughput and recovery. Once through the blades, multiple side pressure rollers engage the log on the outfeed, further reducing the chance of the log moving during the sawing process. Once clear of the blades, the side pressure rollers release, and the two slabs drop down, typically onto a slab cross-feed for further processing. The cant will continue straight, and be pneumatically kicked off and conveyed to the next step in the sawing process. The TV2000 is ideal for pallet mill and stud mill operations, where the product has relatively small cross-sectional dimensions.

The TV4000 and TV6000 are our larger and most robust primary breakdown twin-vertical saws. Both models make use of the same heavy duty, automated infeed and outfeed systems, but differ in blade size and production capacity. These models can handle a high throughput of small to medium diameter logs and a maximum log length of 6.6 m. The main priority at this primary stage in the log breakdown process is to achieve equal open faces on the sawn cant. This allows for higher recovery down the line at the multirip or gang saw. Our Twinbands achieve equal open face cutting using a fast and accurate log loading system coupled with pressurised hold-down rollers and a spiky-feed chain.