How to Saw Logs into Lumber

By Wood-Mizer, Canada

There are many different sawing methods and techniques to turn logs into lumber including live sawing, cant sawing, plain sawing, grade sawing, and quarter sawing. To get you started, here is an introductory course in sawing your logs to lumber.

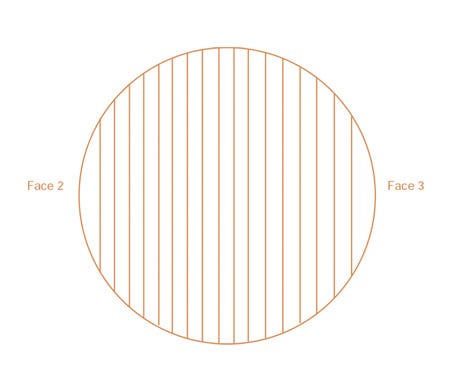

Live Sawing

Live sawing, also known as slab sawing or through and through sawing, is when a log is sawn about halfway through on the opening face and then turned once to the opposite face for sawing until the log is finished. Although this can be the easiest and quickest sawing method, live sawing means that every piece of lumber must be edged after it has been sawn to get the highest value. Live sawn lumber is often wide and heavy, lower in grade, and can have excessive warp during the drying process. Live sawing is generally recommended for lower quality logs because of these disadvantages.

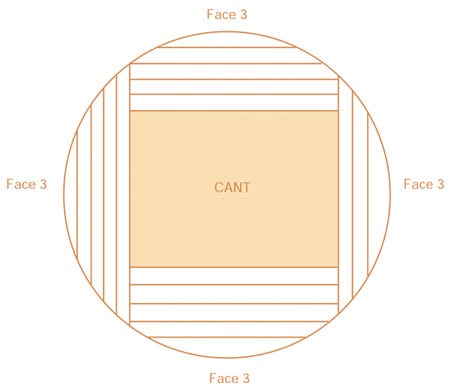

Cant Sawing

With cant sawing, the first cuts are made across the top of the log and flipped 180 degrees to saw the second cuts across the opposite face. Once rotated 90 degrees to saw the third side, and rotated another 180 degrees to saw the last side, the log is squared into a center piece called a cant. This cant is either sent to another machine for further processing or sold as a large and heavy timber. Cant sawing maximizes sawmill production in board feet per day and is commonly used throughout the hardwood sawing industry. Primarily used on medium and low quality logs, cant sawing can save valuable time and effort when working with low grade and low value lumber.

Plain Sawing

Similar to cant sawing, plain sawing begins with rotating and sawing the outer sides of a log into boards until the center is squared into a four-sided cant. Instead of leaving the cant as is, it is rotated and sawn to produce the maximum amount of lumber. If needed, the boards are then edged by sawing the rough edge off. Although there are many different techniques for achieving the best quality and yield from a log, anyone can get great lumber from plain sawing.

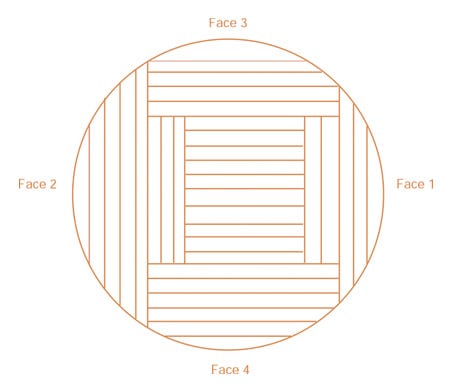

Grade Sawing

With grade sawing, the log is sawn, turned to a new face, sawn and turned again as many as five times. Financially, grade sawing is the best sawing method for medium and high-quality logs, even though it may be difficult to turn a log on some mills and daily production volume may be lower.

There are many different sawing methods and techniques to turn logs into lumber including live sawing, cant sawing, plain sawing, grade sawing, and quarter sawing. To get you started, here is an introductory course in sawing your logs to lumber.

Live Sawing

Live sawing, also known as slab sawing or through and through sawing, is when a log is sawn about halfway through on the opening face and then turned once to the opposite face for sawing until the log is finished. Although this can be the easiest and quickest sawing method, live sawing means that every piece of lumber must be edged after it has been sawn to get the highest value. Live sawn lumber is often wide and heavy, lower in grade, and can have excessive warp during the drying process. Live sawing is generally recommended for lower quality logs because of these disadvantages.

Cant Sawing

With cant sawing, the first cuts are made across the top of the log and flipped 180 degrees to saw the second cuts across the opposite face. Once rotated 90 degrees to saw the third side, and rotated another 180 degrees to saw the last side, the log is squared into a center piece called a cant. This cant is either sent to another machine for further processing or sold as a large and heavy timber. Cant sawing maximizes sawmill production in board feet per day and is commonly used throughout the hardwood sawing industry. Primarily used on medium and low quality logs, cant sawing can save valuable time and effort when working with low grade and low value lumber.

Plain Sawing

Similar to cant sawing, plain sawing begins with rotating and sawing the outer sides of a log into boards until the center is squared into a four-sided cant. Instead of leaving the cant as is, it is rotated and sawn to produce the maximum amount of lumber. If needed, the boards are then edged by sawing the rough edge off. Although there are many different techniques for achieving the best quality and yield from a log, anyone can get great lumber from plain sawing.

Grade Sawing

With grade sawing, the log is sawn, turned to a new face, sawn and turned again as many as five times. Financially, grade sawing is the best sawing method for medium and high-quality logs, even though it may be difficult to turn a log on some mills and daily production volume may be lower.