Portable Sawmills

Since 1982, Wood-Mizer has brought personal and portable sawmills to people all over the world who want the freedom of sawing their own lumber for projects or profits. Engineered for performance and quality, Wood-Mizer offers a complete line of sawmills for woodworking hobbyists to full-time sawmill operators. Stationary or portable, manual or hydraulic, standard or wide, monorail or twin rail, it’s your choice and it’s all available from Wood-Mizer.

Wood-Mizer Blades Are Unmatched Across the Board

Unmatched Performance

At the heart of every great sawmill and resaw are the industry’s best sawmill blades. To ensure the ultimate sawmill blade performance across the board, Wood-Mizer designs and manufactures our own blades and is the only portable sawmill equipment manufacturer that does so.

Unmatched Selection

From sawing green softwoods to abrasive hardwoods, Wood-Mizer offers an extensive range of sawmill bandsaw blades with more than 100 combinations based on profile, width, thickness, tooth spacing, and material for any type of sawing or resawing application.

Unmatched Quality

Each Wood-Mizer sawmill blade tooth is precisely set by computer-controlled equipment and completely profile ground tip to tip using super abrasive CBN grinding technology. From the selection of raw steel to performing more than 100 tests and inspections through the final grind, we are dedicated to providing the highest quality sawmill blades on the market.

Unmatched Compatibility

Wood-Mizer gives you more choices by manufacturing sawmill blades for Wood-Mizer, Baker, Cooks, Hud-Son, Norwood, Timberking, Timbery, Woodland Mills, and more band sawmills and resaws!

The Ultimate Guide to Sawmill Blades

Learn everything you need to know about sawmill bandsaw blades with the Ultimate Guide to Sawmill Blades free guide download from Wood-Mizer! This helpful guide is packed with sawmill blades tips and how-to including:

- What are Sawmill Blades Made Of?

- How to Choose a Sawmill Blade Profile

- How to Shop for Sawmill Blades

- How to Safely Unpack Your Sawmill Blades

- How to Fold and Unfold a Sawmill Blade

- How to Change a Sawmill Blade

- How to Store Sawmill Blades

- How to Increase Your Sawmill Blade Life

- Ten Winter Sawing Tips

- And More!

Sawmill Blades and Bandsaw Mill Blades

Using the best sawmill blade is key to increasing production, improving cut quality, and reducing costs for your sawmilling or resawing operation. From sawing green softwoods to abrasive hardwoods, Wood-Mizer offers an extensive range of sawmill bandsaw blades with more than 100 combinations based on profile, width, thickness, tooth spacing, and steel material. Each Wood-Mizer sawmill blade tooth is precisely set by computer-controlled equipment and completely profile ground tip to tip using super abrasive CBN grinding technology to ensure you consistently receive the highest quality sawmill blade performance. Wood-Mizer gives you more choices by manufacturing sawmill blades for Wood-Mizer, Baker, Cooks, Hud-Son, Norwood, Timberking, Timbery, Woodland Mills, and more band sawmills and resaws! Shop Wood-Mizer sawmill blades in Canada for unmatched quality, accuracy, and performance across the board. Also keep your sawmill blades sharp with Wood-Mizer bandsaw blade sharpeners and tooth setters.

Unmatched Across the Globe

Wood-Mizer Blades

- Making Blades Since 1982

- Produced Enough Blades To Circle The Earth 3 Times

- More Than 100 Combinations For All Types of Sawing and Resawing

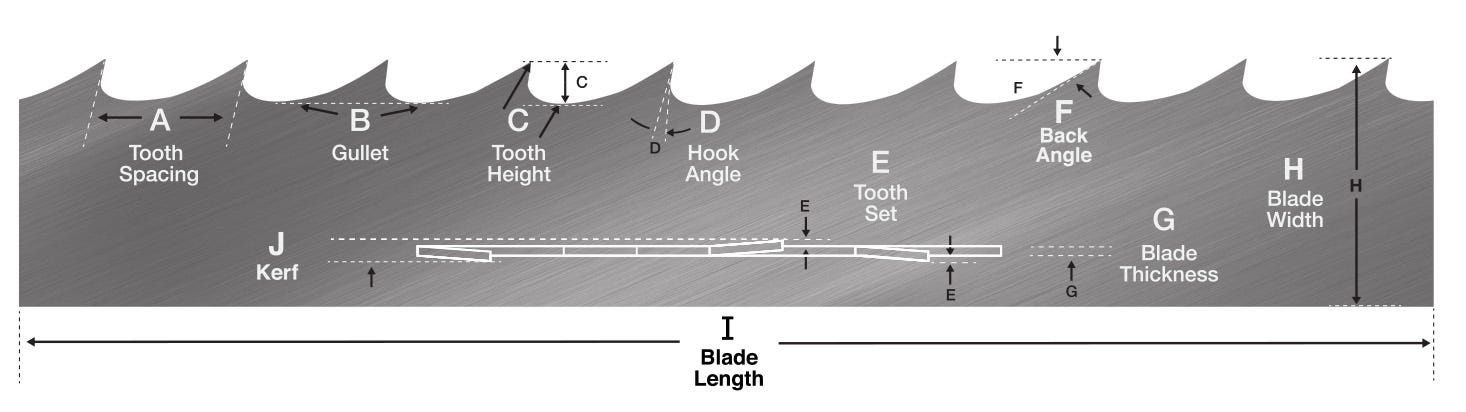

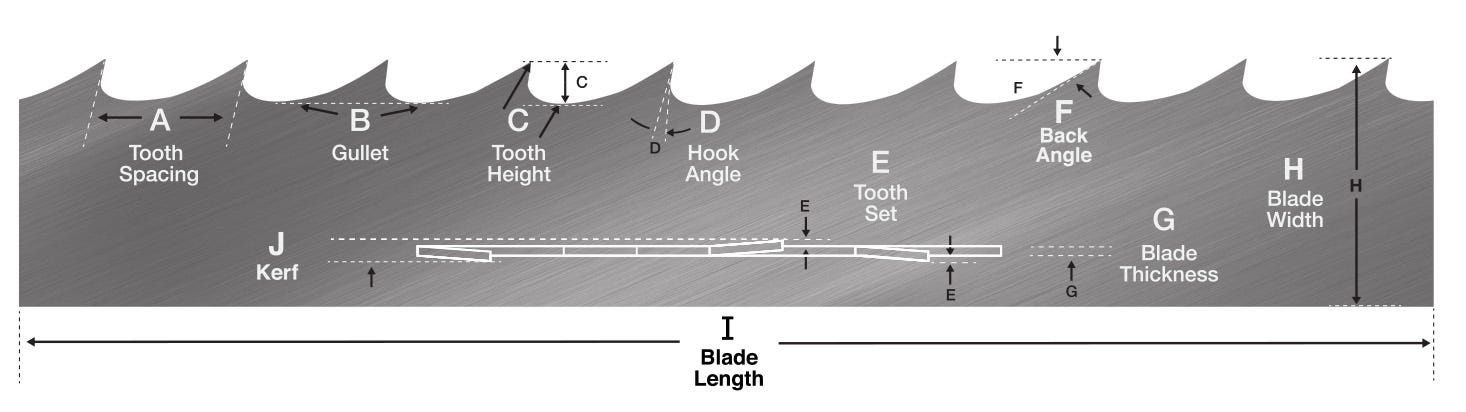

Blade Terminology

A. Tooth Spacing - is the distance between each tooth from one tip to another.

B. Gullet - Captures and removes sawdust.

C. Tooth Height - is the distance from the lowest point of the gullet to the tip of the tooth.

D. Hook Angle - is the number of degrees that the tooth leans forward of 90 degrees.

E. Tooth Set - the distance the tooth is bent beyond the body of the blade.

F. Back Angle - Angle of the backside of the tooth from 90 degrees.

G. Blade Thickness - Thinner blades (.035", .038", .042") are designed for lower horspower sawmills, and thicker blades (.045", .050", .055") are for higher horsepower .

H. Blade Width - distance between the tip and base of the blade. Wider blades for high horsepower sawmills and a faster feed rate. Use a narrow blade for lower horsepower sawmills and for more difficult sawing.

I. Blade Length - the distance between the ends of the sawmill blade before welding

J. Kerf - Width of cut measuring from one side of the tooth set to the other side tooth. This measurement determines how much wood is removed with each pass.

HOW TO KEEP YOUR BLADES SHARP:

Wood-Mizer Blade Maintenance Equipment

Wood-Mizer manufactures a professional line of sawmill bandsaw blade sharpeners and tooth setters to help your bandsaw mill blades deliver maximum performance with each cut.